Your cart is currently empty!

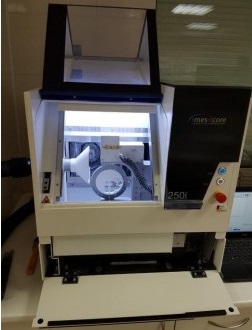

Planmeca PlanMill 50 S Milling Unit

Planmeca PlanMill 50 S Milling Unit Planmeca PlanMill 50 S Milling Unit is a high-precision dental milling unit designed for efficient production of restorations like crowns, bridges, and veneers. It supports a variety of materials, features a user-friendly touchscreen interface, and integrates seamlessly with Planmeca’s CAD/CAM systems. With its compact design and fast milling speeds,…

Description

Planmeca PlanMill 50 S Milling Unit

Planmeca PlanMill 50 S is a sophisticated dental milling unit designed for efficient and precise production of dental restorations. Here are some key features and aspects:

Key Features

- High Precision: The unit utilizes advanced milling technology to ensure high accuracy and excellent surface quality in restorations.

- Versatile Material Compatibility: It can work with a wide range of materials, including zirconia, ceramics, and PMMA, making it suitable for various applications.

- User-Friendly Interface: The touchscreen interface is intuitive, allowing for easy operation and quick adjustments during the milling process.

- Compact Design: Its compact size makes it suitable for both large and small dental practices without taking up too much space.

- Integrated Workflow: The PlanMill 50 S seamlessly integrates with Planmeca’s CAD/CAM systems, ensuring a smooth workflow from design to production.

- Fast Milling Speed: The unit is designed for efficient milling, significantly reducing production time while maintaining quality.

- Quiet Operation: It operates quietly, creating a more comfortable working environment.

Applications

- Crowns and Bridges: Ideal for creating high-quality single crowns and multi-unit bridges.

- Implant Restorations: Can be used for producing custom implant abutments and restorations.

- Veneers and Inlays: Suitable for creating esthetic veneers and inlays with precision.

Considerations

- Initial Investment: While the milling unit is a significant investment, it can lead to cost savings over time by reducing outsourcing needs.

- Training: Staff may require training to operate the unit effectively and to utilize its full capabilities.

Maintenance

- Regular maintenance and calibration are essential to keep the milling unit in optimal condition and ensure consistent performance.

Highlights

• 5-axis milling unit for dental applications

• Discs and blocks, milling and grinding

• Wet and dry processing

• 12 tool automatic changer (measurement and tool check

after each processing step)

• Integrated PC with touchscreen

• Easy to use control software

• Indication support for bite splints, hybrid abutments and 3D models

• Yearly maintenance and calibration check-up by technician

• User maintenance (tools, cleaning, spindle, coolant tank)

Dimensions when closed (W x H x D) 566 x 612 x 665 mm (22.3 x 24.1 x 26.2 in.)

Weight 95 kg (209.4 lbs)

Cover Swivel hood with safety interlocking

Consumption of compressed air Approx. 60 l/min (min. 6,5 bar)

Spindle 60 000 rpm

Tool Changer 12 tool positions, automated

CAM software Automated toolpath calculation with Planmeca PlanCAM™ software

Reviews

There are no reviews yet.